TRUNNANO Unveils Revolutionary Alkali-Resistant, High Thermal Conductivity Ceramic Crucible

LUOYANG, China, Nov. 10, 2025 (GLOBE NEWSWIRE) -- TRUNNANO, a global leader in advanced ceramic materials manufacturing, today officially launched its breakthrough product: an alkali-resistant, high-thermal-conductivity silicon carbide ceramic crucible specifically engineered for high-temperature melting of sodium-ion, lithium-ion, potassium-ion, air battery, and solid-state battery materials. This innovation successfully addresses the durability challenges faced by traditional crucible materials under extreme high temperatures and strong alkaline conditions, establishing a new industry benchmark for next-generation battery material manufacturing.

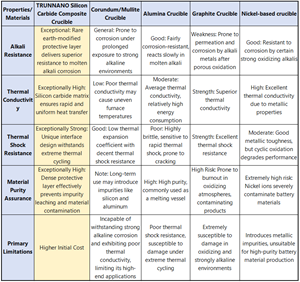

Amid the rapid development of the new energy industry, the high-temperature synthesis process for battery materials imposes increasingly stringent demands on the performance of melting vessels. Common crucibles on the market—such as cordierite mullite, corundum mullite, alumina, graphite, and nickel-based crucibles—all exhibit limitations to varying degrees, struggling to simultaneously meet the comprehensive demands of high thermal conductivity, strong alkali resistance, and excellent thermal shock resistance.

![]()

TRUNNANO silicon carbide ceramic crucible

Mr. Roger Luo, CEO of TRUNNANO, noted: "Existing material solutions often require compromises when confronting extreme smelting environments. For instance, graphite crucibles offer outstanding thermal conductivity but have limited lifespan under high-temperature oxidation and strong alkali corrosion. Aluminum oxide and mullite crucibles demonstrate acceptable alkali resistance but suffer from relatively low thermal conductivity. Nickel-based crucibles, meanwhile, face issues of high cost and potential material contamination in specific media. Our new technology was developed precisely to overcome these limitations."

TRUNNANO's innovative crucibles are based on a high-performance silicon carbide composite ceramic matrix, combined with our proprietary “in-situ bonded rare-earth modified composite oxide protective layer” technology. Compared to traditional materials, they demonstrate significant advantages:

Compared to cordierite and corundum mullite materials, TRUNNANO crucibles' rare-earth-modified protective layer demonstrates superior chemical stability and resistance to permeation in high-temperature caustic environments, effectively extending service life in highly corrosive conditions.

Moreover, the silicon carbide matrix delivers thermal conductivity far exceeding traditional alumina and mullite materials, ensuring rapid and uniform heat transfer during smelting while overcoming the limitations of graphite in high-temperature oxidation environments.

Additionally, unlike nickel-based crucibles, TRUNNANO crucibles completely eliminate the risk of metal ion contamination, providing reliable assurance for producing high-purity battery materials.

Performance Comparison of Crucibles Made from Different Materials in High-Temperature Melting of Battery Materials:

“We're not merely offering an alternative,” emphasized Roger Luo. “We're redefining the performance standards for high-temperature melting vessels. This crucible establishes a new equilibrium in thermal conductivity, corrosion resistance, and service life, enabling customers to enhance product quality while optimizing production costs.”

The product launch is expected to positively impact manufacturing processes for key materials in sodium-ion, lithium-ion, and potassium-ion batteries, providing robust support for large-scale, high-purity production of advanced battery materials. TRUNNANO stands ready to engage in deep collaboration with global battery material manufacturers to jointly drive innovation in the new energy industry.

TRUNNANO remains committed to delivering reliable solutions for global industrial advancement through breakthroughs in materials science. The company will continue to increase R&D investment, providing more groundbreaking advanced ceramic products for high-end manufacturing.

About TRUNNANO

TRUNNANO is a high-tech enterprise specializing in the development, manufacturing, and commercialization of nanomaterials, high-end ceramic products, and other high-purity chemicals. Driven by technological innovation, its products are widely used in various industrial fields. With its superior product quality and professional technical service, TRUNNANO has earned the trust of customers worldwide. Under the leadership of CEO Roger Luo, TRUNNANO is committed to promoting the advancement of materials science through continuous technological breakthroughs and contributing to global industrial development.

Media Contact: Roger Luo

Email: nanotrun@yahoo.com / sales8@nanotrun.com

Phone/WhatsApp: 0086 18837956556

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/4aea67d0-3ad9-4145-ab56-06d24997709e

https://www.globenewswire.com/NewsRoom/AttachmentNg/967cd393-bf45-40f5-b2cc-4eb5c7d8d283

Performance Comparison of Crucibles Made from Different Materials in High-Temperature Melting of Battery Materials

Direct comparison of crucible materials subjected to the high-temperature melting of aggressive battery materials (e.g., NMC precursors, lithium cobalt oxide). The visual results clearly show differences in corrosion resistance, slag formation, and structural integrity, highlighting the critical role of crucible selection in process efficiency and material purity.

TRUNNANO silicon carbide ceramic crucible

TRUNNANO Silicon Carbide (SiC) Ceramic Crucible: Engineered for exceptional thermal shock resistance, high thermal conductivity, and long service life in extreme temperature environments.

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.